HOME

/ MAINTENANCE / Testing Machine

Testing Machine

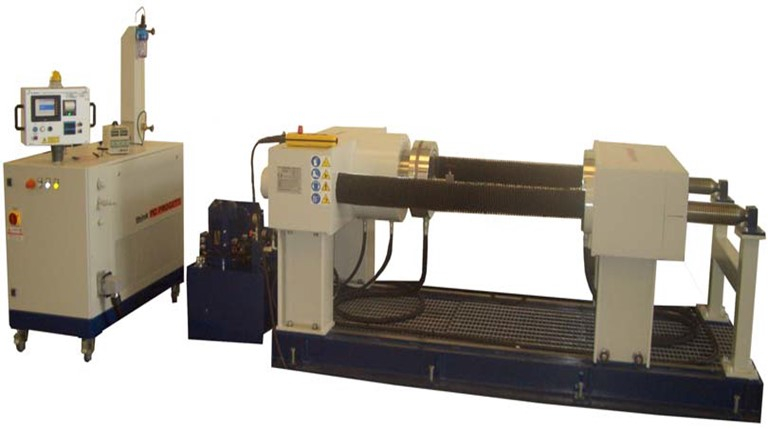

Control Valve Testing Machine

Range of Use: 2 inches ~ 24 inches, pressure rating of ANSI 150 ~ ANSI 2500, leakage rating of II ~ VI‚ Air test pressure range 0.5 ~ 7 Kg/cm2, pressure resistance test pressure range 3.5 ~ 700 Kg/cm2.

Functions: The machine is designed according to the regulations of ANSI FCI 70-2, API-598 Automated Testing, and capable of performing leak and pressure closure tests.

Advantages: Capable of connecting to computer program test system to directly judge whether or not the test data is qualified or not to avoid downtime of client's production system from manual judgment errors.

Safety Valve Testing Machine

Range of Use: 0.5 inch ~ 10 inch, capable of testing pressure 200 bar

Functions: The machine is designed according to the regulations of API-527 Automated Testing

Advantages: Capable of connecting to computer program test system to directly judge whether the test data is qualified or not to avoid downtime of client's production system from manual judgment errors.

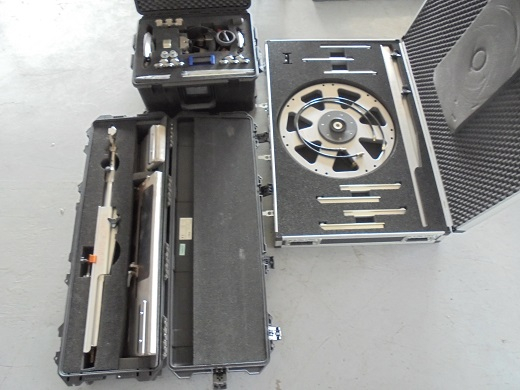

Mobile Safety Valve Testing Machine

Range of Use: 0.5 inch ~ 10 inch, capable of testing pressure 200 bar

Functions: The machine is designed according to the regulations of API-527 Automated Testing

Advantages: In addition to the advantages of the Safety Valve Testing Machine listed above, it has excellent maneuverability and capable of testing at the client's plant site directly to reduce the project time and facilitate the work inspection schedules.

Safety Valve / Boiler On-line Testing Equipment

Range of Use: Used for the on-site power boiler inspection and adjustment of trip pressure for the safety valves.

Functions: Generally known on-line testing is to raise the pressure to trip directly at the set pressure of the safety valve. This test method is very expensive and wasteful, and easy to damage the sealing tightness for the valve seat.

Using the Company's equipment has low energy consumption and low cost. The Company's equipment computer can display the reports directly with credibility.

Maintenance Equipment

Fixed Surface Grinding Machine

Range of Use: Gate valve 1/4 inch ~ 24 inch, angle of inclination: 0 ~ 12 degrees.

Functions: Capable of grinding the valve seat surface of valve types to flat.

Advantages: The machine can be used to perform the works that cannot be done with manual grinding. It also greatly reduces the grinding time and damages caused by unevenness of the valve seat surface due to manual grinding.

Mobile Grinding Machine

Range of Use: Gate valve 1/4 inch ~ 24 inch, angle of inclination: 0 ~ 12 degrees, the minimum depth of the valve body size is 165mm, and the maximum size is 1500mm.

Functions: Capable of grinding the valve seat surface of valve types to flat.

Advantages: It has excellent maneuverability and capable of grinding at the client's site directly. The machine can be used to perform the works that cannot be done with manual grinding. It also greatly reduces the grinding time and damage caused by unevenness of the valve seat surface due to manual grinding.

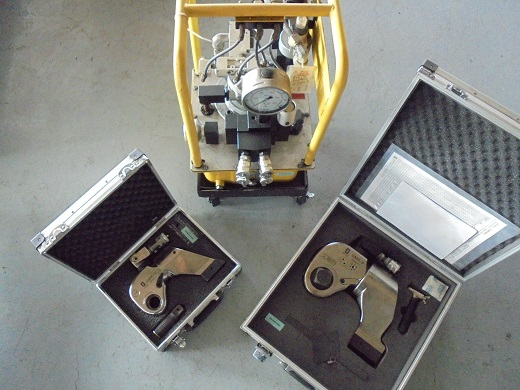

Hydraulic Pump and Hydraulic Wrench

Range of Use: Bolt range: 22 ~ 64mm, output pressure 645 N-m ~ 10780 N-m

Functions: Using the air source to drive the hydraulic wrench. The hydraulic wrench can replace manpower to reach the torque value of the nut that cannot be locked securely.

Advantages: Conducive to the use in explosion-proof construction areas, capable of averaging the torque value of locking nut to prevent damage from the nut deformation and bolt pulling. It can also protect the valve assembly component from being damaged by manual unilateral force.

Sand-blasting Machine

Range of Use: Working space of 80 cm*80 cm

Functions: Stripping of rust, scale, painting, grinding and cleaning of casting project, grinding and cleaning of convex-concave areas, etc.

Advantages: Rust removal, stripping of painting with and fast working speed and capable of checking the valve body for abnormal sand holes.